It’s not every day that we have the opportunity to interview one of our customers on the other side of the Atlantic! This correspondent is none other than the prestigious California Institute of Technology (CALTECH) through two researchers, Dr. Israel Kellersztein and Prof. Chiara Daraio from Caltech’s Department of Mechanical and Civil Engineering. In this interview, we talk to these researchers about their groundbreaking research into the use of chlorella as a natural building material. They are exploring the unique properties of microalgae for sustainable construction, driven by the desire to create environmentally friendly materials.

A key aspect of their research is the purity of chlorella, which is crucial to obtaining consistent, reliable results. That’s why they chose Chlorella eChlorial, renowned for its exceptional purity, and have been using it for several years. This choice underlines the importance of high-quality materials in scientific advances. In this discussion, Dr. Kellersztein and Prof. Daraio share their motivations, results and the potential future of chlorella-based materials in the construction industry. They are expecting to publish a paper on these materials on an international scientific peer review journal.

How did you get interested in studying Chlorella for structural materials?

Our interest in studying Chlorella as a natural material for structural applications arose from a desire to address environmental concerns and explore innovative and sustainable solutions for new packaging and construction materials that do not rely on synthetic polymers. We were intrigued by Chlorella’s distinctive characteristics, including its rapid growth rate, complex biochemical composition, and cell shape and size. The prospect of contributing to eco-friendly material production motivated us to delve into researching Chlorella for structural applications.

What makes Chlorella good for use in structural materials?

There are various characteristic properties of Chlorella cells that position them as a suitable candidate for structural applications. Chlorella can be cultivated rapidly and sustainably, making it an environmentally friendly and renewable resource. The cells have a large surface area due to their small size and spherical shape, which is particularly important for promoting interactions with other materials when designing composites.

One of the most important properties of Chlorella lies in its cell wall. This external thin layer is responsible for several critical functions, including structural support, protection, and permeability of the cell. In the case of Chlorella, the cell wall is rich in cellulose, a very stiff and strong biopolymer. The robust cellulose-based cell wall provides the necessary rigidity and strength for various applications. Maintaining the cell wall intact and conserving the spherical shape of Chlorella are critical for designing successful structural materials based on Chlorella cells. These properties make Chlorella a promising material for creating strong, lightweight, and sustainable structural materials.

Why is the purity of Chlorella important for its use in structural materials?

The presence of additional components, or impurities, in Chlorella can drastically affect its properties, including its mechanical performance. As scientists and engineers, our goal is to design materials with consistent mechanical properties. In the case of Chlorella-based materials, we aim to produce structures that behave the same all the time.

To achieve this, Chlorella must be as pure as possible. Otherwise, the properties of the final material will be affected by contaminants, which may interact weakly with Chlorella cells, resulting in discontinuities and defects. Having pure Chlorella material is crucial because it ensures the reliability and durability of the resulting structures, making them effective as structural materials.

What are the benefits of Chlorella-based materials compared to traditional materials?

Synthetic polymer materials, such as polyethylene or polypropylene, are derived from raw materials obtained from fossil fuels, including petroleum or natural gas. This production process is energy intensive. Additionally, synthetic polymers are non-biodegradable, leading to environmental pollution when disposed of, as they release harmful chemicals and pollutants into the environment.

Biodegradable polymers, such as polylactic acid, offer an alternative but are associated with high extraction and production costs. Furthermore, the cultivation of natural crops for monomer extraction may involve the use of fertilizers, resulting in pollution and competition for food resources. Deforestation, as seen with wood, contributes to global warming by raising soil temperatures.

Using Chlorella as a natural resource for material design offers numerous benefits. It promotes environmental preservation, resource conservation, and climate mitigation. Chlorella, a photosynthetic microorganism, absorbs more carbon dioxide than terrestrial plants. It can thrive in various environments without competing for agricultural land.

Utilizing Chlorella supports the transition to a circular economy, where products are designed for reuse or recycling at the end of their life cycle.

What challenges do you face in developing Chlorella as a sustainable material?

Microalgae have long been a subject of research in the life sciences, serving as a model system for understanding cell proliferation mechanisms and photosynthetic activities, among others. In the field of materials science, microalgae represent a new class of resources for designing novel biomaterials with structural capabilities.

Microalgae cells are composed of various materials, including proteins, lipids, and polysaccharides, rendering them a complex system. Additionally, the morphology and characteristics of the cell wall are intricate, necessitating further research to fully comprehend how chlorella-based materials can be processed and improved.

This entails investigating potential interactions between chlorella cells and natural or synthetic reinforcements, as well as understanding the effects of different processing parameters such as pressure, temperature, or viscosity when designing these materials.

What is the future of Chlorella in building and packaging industries, and what steps are you taking to make it happen?

We anticipate seeing not only Chlorella but also other microalgae strains involved in various applications, including packaging and construction. Preliminary research indicates comparable mechanical capabilities of these materials to commodity polymers, such as polypropylene or polyethylene. Additionally, algae-based materials offer potential for different functionalities beyond mechanical properties, such as thermal or acoustic insulation.

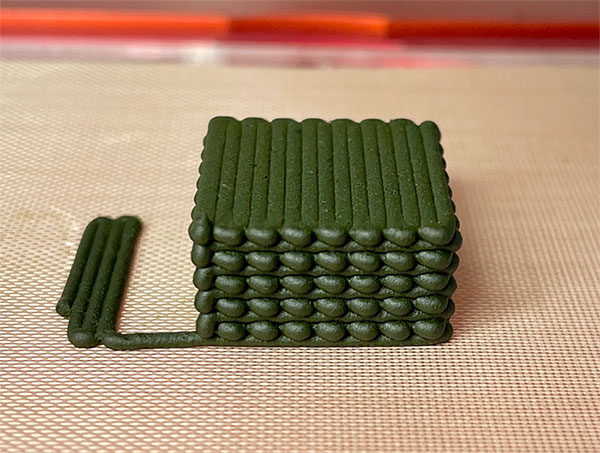

Significant efforts are currently underway to develop processing methods, with a focus on 3D printing, which offers a more sustainable process allowing for the design of more complex shapes. Furthermore, ongoing research is exploring compression molding of spirulina or wastewater-derived algae.

***

Interested in this topic? Please contact us for more information.